In the rapidly evolving smart home ecosystem, smart sensors have emerged as the essential foundation that enables truly intelligent living spaces. As we navigate through 2025, the smart sensor market continues to demonstrate remarkable growth and technological advancement, creating significant opportunities for importers and manufacturers alike.

At SWITCH GO, a leading smart home technology company based in Shenzhen since our founding in 2019, we’ve been at the forefront of smart sensor innovation with our philosophy of “Switch Smarter, Live Easier.” Our experience as both manufacturers and market participants provides us with unique insights into what makes smart sensors an attractive product category with substantial commercial potential.

This comprehensive guide explores everything importers and manufacturers need to know about smart sensors in 2025 – from market trends and certification requirements to technical specifications and manufacturing considerations. Whether you’re looking to enter this dynamic market or optimize your existing smart sensor business, this article provides the essential knowledge to succeed.

Smart Sensor Market Overview: Explosive Growth and Diverse Applications

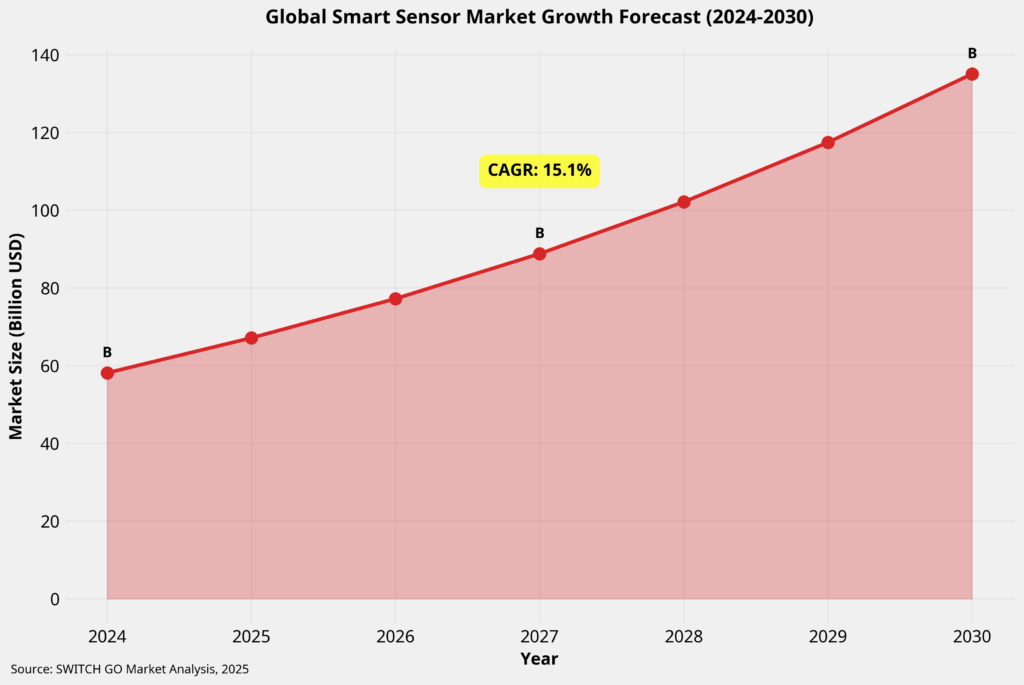

The global smart sensor market has demonstrated exceptional growth in recent years, with a clear upward trajectory projected through 2030. According to our analysis at SWITCH GO, the market valued at approximately $58.16 billion in 2024 is projected to reach $135.09 billion by 2030, growing at a compound annual growth rate (CAGR) of 15.1%.

Global Smart Sensor Market Growth Forecast (2024-2030)

This impressive growth rate reflects the expanding role of sensors across multiple domains:

- Smart home integration: Sensors form the foundation of home automation, enabling systems to respond to environmental changes and user behaviors.

- IoT ecosystem expansion: The broader Internet of Things revolution relies heavily on sensor technology to gather real-world data.

- Energy efficiency initiatives: Smart sensors enable precise monitoring and control of energy consumption in residential and commercial settings.

- Health and wellness applications: Environmental monitoring sensors contribute to healthier living spaces by tracking air quality, temperature, and humidity.

- Security enhancement: Motion, door/window, and other security sensors provide the first line of defense in smart security systems.

The market is diverse, with several sensor types dominating different application segments:

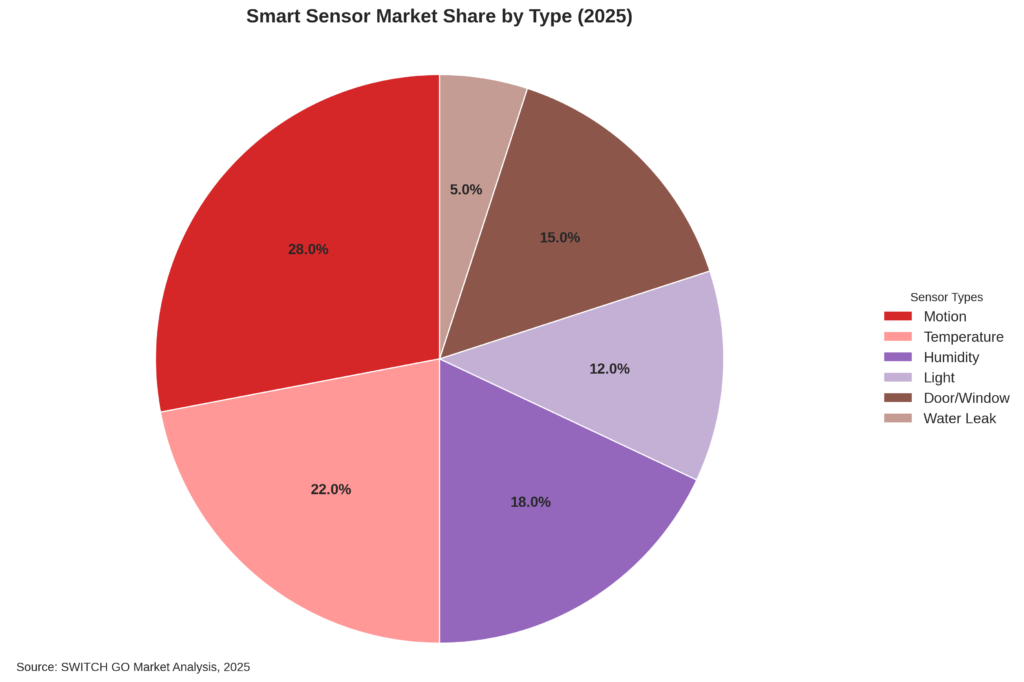

Smart Sensor Market Share by Type (2025)

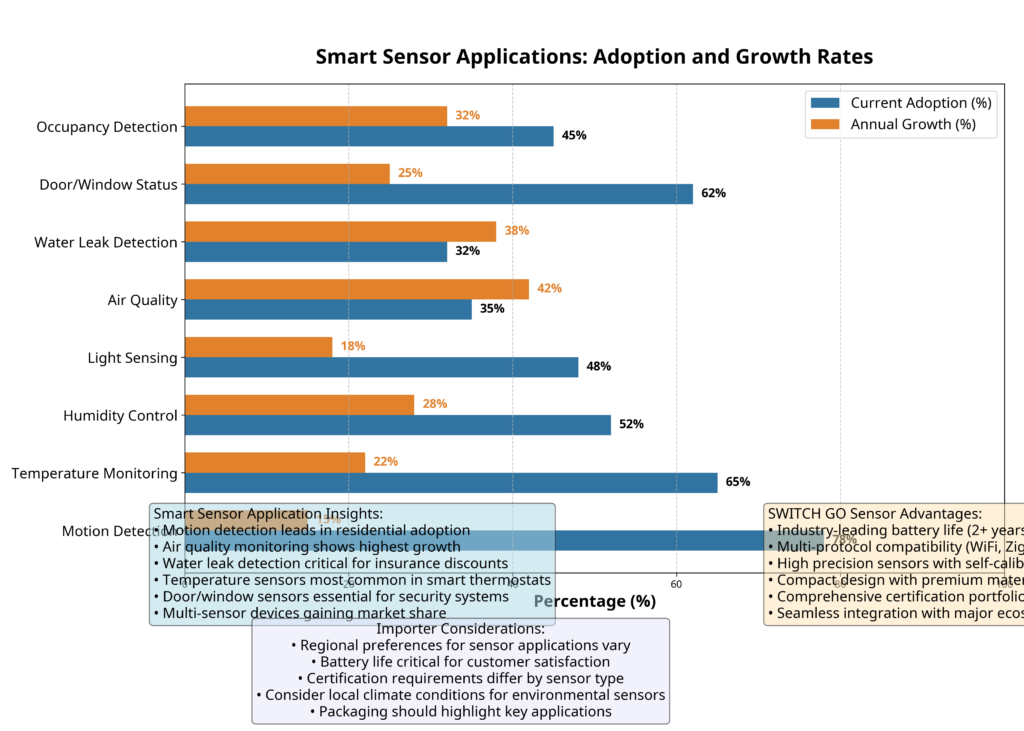

Motion sensors currently lead the market with 28% share, followed by temperature sensors (22%) and humidity sensors (18%). Door/window sensors account for 15% of the market, while light sensors represent 12%. Water leak sensors, though smaller at 5%, are experiencing rapid growth due to increasing awareness of water damage risks.

Regional analysis reveals interesting market dynamics. North America currently leads with approximately 38% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth, with China emerging as both a manufacturing powerhouse and rapidly growing consumer market.

For importers and manufacturers, understanding these regional differences is crucial. North American consumers typically prioritize seamless integration with existing smart home ecosystems and robust security features. European buyers often place greater emphasis on energy efficiency and environmental monitoring capabilities. In Asia-Pacific markets, competitive pricing and multi-functionality tend to be key purchasing factors.

Types of Smart Sensors and Their Applications

The smart sensor landscape encompasses a diverse range of technologies, each serving specific functions within the smart home ecosystem. Understanding these different sensor types and their applications is essential for importers and manufacturers looking to target specific market segments.

Motion Sensors

Motion sensors detect movement within their field of view and are fundamental components in security systems and automated lighting control.

| Technology | Detection Range | Power Requirements | Best Applications | Limitations |

|---|---|---|---|---|

| Passive Infrared (PIR) | 15-30 feet | Low (battery-operated viable) | Security, lighting automation | Cannot detect stationary objects |

| Microwave | 50-100 feet | Medium | Large area coverage, outdoor applications | Higher power consumption, potential interference |

| Ultrasonic | 15-25 feet | Medium | Enclosed spaces, precise detection | Limited range, potential false triggers |

| Dual Technology (PIR+Microwave) | 30-50 feet | Medium-High | High-security areas, reduction of false alarms | Higher cost, more complex setup |

At SWITCH GO, our most popular motion sensor utilizes PIR technology with advanced algorithms to minimize false triggers while maintaining excellent battery life – a critical consideration for wireless installations.

Temperature and Humidity Sensors

These environmental sensors monitor ambient conditions and enable climate control automation, energy efficiency, and comfort optimization.

| Sensor Type | Accuracy | Response Time | Power Requirements | Best Applications |

|---|---|---|---|---|

| Thermistor-based | ±0.5°C | 5-10 seconds | Very Low | Basic temperature monitoring |

| Digital temperature IC | ±0.2°C | 1-2 seconds | Low | Precise climate control |

| Capacitive humidity | ±3% RH | 8-15 seconds | Low | General humidity monitoring |

| Polymer humidity | ±2% RH | 4-8 seconds | Low | Precise humidity control |

| Combined temp/humidity | Varies | Varies | Low | Integrated climate monitoring |

Our research indicates that combined temperature and humidity sensors offer the best value proposition for most smart home applications, reducing installation complexity while providing comprehensive environmental data.

Door and Window Sensors

These contact sensors detect the opening and closing of doors, windows, cabinets, and other movable surfaces, forming the backbone of security systems and enabling conditional automation.

| Technology | Detection Method | Power Requirements | Installation Complexity | Best Applications |

|---|---|---|---|---|

| Reed switch | Magnetic | Very Low | Simple | Basic security, automation triggers |

| Optical | Light beam interruption | Low | Medium | High-security applications |

| Accelerometer-based | Motion/vibration | Low | Simple | Multi-purpose detection (open/close/knock) |

| Capacitive | Proximity | Low | Simple | Hidden installation, aesthetic applications |

Door and window sensors represent an excellent entry point for manufacturers new to the smart sensor market, as they combine relatively simple technology with high consumer demand and multiple use cases.

Light Sensors

Light sensors detect ambient light levels and enable automated lighting control, energy efficiency, and circadian rhythm support through dynamic lighting adjustments.

| Sensor Type | Sensitivity Range | Spectral Response | Power Requirements | Best Applications |

|---|---|---|---|---|

| Photoresistor | Wide | Broad spectrum | Very Low | Basic light detection |

| Photodiode | High | Narrow band | Low | Precise light measurement |

| Ambient Light Sensor IC | Very High | Human eye approximation | Low | Human-centric lighting |

| UV Light Sensor | Specialized | Ultraviolet spectrum | Low | Sun exposure monitoring |

Light sensors are increasingly being integrated with other sensor types to create multi-functional devices that provide comprehensive environmental monitoring.

Water Leak Sensors

These specialized sensors detect the presence of water or moisture and provide early warning of leaks, helping prevent costly water damage.

| Technology | Detection Method | Installation Location | Power Requirements | Best Applications |

|---|---|---|---|---|

| Contact probes | Direct water contact | Floor level | Very Low | Point detection (under sinks, appliances) |

| Conductive tape/cable | Water contact along length | Perimeter/linear | Low | Extended area coverage |

| Moisture mat | Absorbent material with conductivity sensing | Floor level | Low | Broad area coverage |

| Ultrasonic | Water level detection | Tank/container mounted | Medium | Water level monitoring |

While representing a smaller market segment, water leak sensors offer significant value proposition through damage prevention, making them attractive products with strong growth potential.

Specialized Sensors

Beyond the core sensor types, several specialized sensors address specific smart home needs:

| Sensor Type | Function | Market Adoption | Growth Potential |

|---|---|---|---|

| Air Quality | Monitors pollutants, VOCs, CO2 | Medium | Very High |

| Smoke/CO | Detects smoke and carbon monoxide | High | Stable |

| Occupancy | Detects human presence (not just motion) | Medium | High |

| Vibration | Detects unusual vibrations (security, appliance monitoring) | Low | Medium |

| Sound | Detects specific sounds (glass break, alarms) | Low | Medium |

| Pressure | Monitors air pressure changes | Very Low | Low |

At SWITCH GO, we’ve seen increasing demand for multi-sensor devices that combine several sensing capabilities in a single unit, offering consumers better value and reducing installation complexity.

We specialize in supplying various intelligent sensor solutions.

Essential Certification Requirements for Smart Sensors

For importers and manufacturers, navigating the complex landscape of certification requirements is essential for market access and consumer trust. At SWITCH GO, we’ve developed expertise in obtaining and maintaining certifications across global markets, and we understand the critical importance of compliance.

North American Certification Requirements

In the United States and Canada, several key certifications are relevant for smart sensors:

| Certification | Description | Applicability | Approximate Cost | Timeline |

|---|---|---|---|---|

| FCC | Electromagnetic compatibility and radio frequency compliance | All wireless sensors | $2,000-$5,000 | 3-6 weeks |

| UL/ETL | Safety standard for electrical devices | Sensors with direct electrical connections | $3,000-$7,000 | 4-8 weeks |

| IC | Canadian radio equipment compliance | All wireless sensors sold in Canada | $1,500-$3,000 | 3-6 weeks |

| Energy Star (optional) | Energy efficiency certification | Applicable to some powered sensors | $3,000-$5,000 | 4-8 weeks |

The FCC certification is particularly critical for wireless sensors, ensuring they don’t cause harmful interference to other electronics. For battery-operated sensors without direct electrical connections to high-voltage sources, UL certification may be less stringent or even unnecessary, depending on the specific design.

European Union Certification Requirements

For the European market, different certifications apply:

| Certification | Description | Applicability | Approximate Cost | Timeline |

|---|---|---|---|---|

| CE | Conformity with health, safety, and environmental protection standards | All sensors | €2,000-€5,000 | 3-6 weeks |

| WEEE | Proper disposal and recycling of electronic waste | All electronic sensors | €1,000-€2,000 | 2-4 weeks |

| RoHS | Restriction of hazardous substances | All electronic sensors | €1,500-€3,000 | 2-4 weeks |

| RED | Radio equipment safety and compatibility | All wireless sensors | €2,000-€4,000 | 3-6 weeks |

The CE (Conformité Européenne) marking is mandatory for products sold in the European Economic Area. While technically a self-declaration, it requires comprehensive testing to demonstrate compliance with all relevant EU directives.

The Radio Equipment Directive (RED) is particularly relevant for wireless sensors, ensuring they meet safety, health, and electromagnetic compatibility requirements.

Asian Market Certification Requirements

For manufacturers targeting Asian markets, several region-specific certifications are necessary:

| Certification | Description | Applicability | Approximate Cost | Timeline |

|---|---|---|---|---|

| CCC (China) | Safety certification for Chinese market | Most electronic sensors | $2,500-$5,000 | 4-8 weeks |

| PSE (Japan) | Japanese safety standard | Powered electronic sensors | $2,000-$4,000 | 3-6 weeks |

| KC (South Korea) | South Korean safety and EMC certification | All electronic sensors | $1,500-$3,500 | 3-6 weeks |

| BIS (India) | Indian safety standard | Electronic sensors | $1,500-$3,000 | 4-8 weeks |

At SWITCH GO, we’ve found that planning for certification early in the product development process significantly reduces time-to-market and avoids costly redesigns. Our recommendation for importers is to verify that manufacturers have obtained all necessary certifications for target markets and can provide complete documentation.

Privacy and Data Security Compliance

Beyond traditional safety and electromagnetic certifications, smart sensors increasingly face privacy and data security requirements:

| Regulation | Region | Requirements | Implications for Sensors |

|---|---|---|---|

| GDPR | European Union | Data protection and privacy | Affects sensors that collect personal data |

| CCPA/CPRA | California, USA | Consumer privacy rights | Impacts data collection and storage practices |

| IoT Security Laws | Various (California, Oregon, UK) | Security requirements for connected devices | Mandates security features for connected sensors |

These regulations can significantly impact product design, particularly for sensors that might collect sensitive data (e.g., occupancy patterns, voice recordings). Manufacturers must implement privacy-by-design principles and appropriate security measures to ensure compliance.

Technical Specifications That Matter

When developing or sourcing smart sensors, understanding the technical specifications that drive market success is crucial. Based on SWITCH GO’s experience in the smart sensor market, we’ve identified the key technical aspects that matter most to consumers and retailers.

Connectivity Options

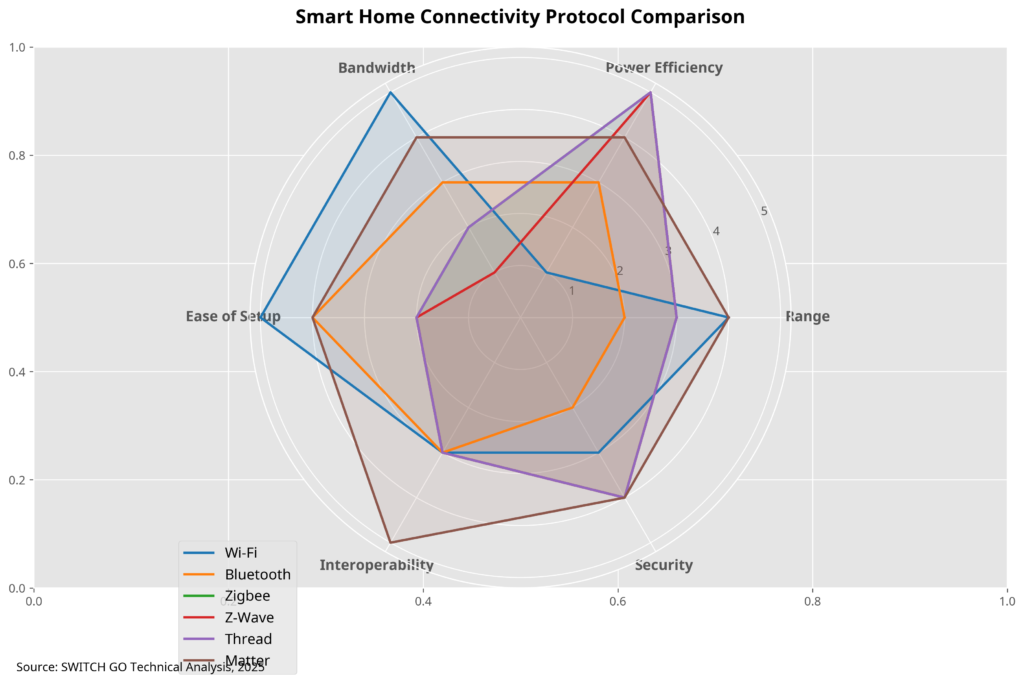

protocol comparison

The choice of connectivity protocol significantly impacts user experience, compatibility, and power consumption:

| Protocol | Advantages | Limitations | Best For |

|---|---|---|---|

| Zigbee | Low power, mesh networking, high reliability | Requires hub/gateway | Battery-operated sensors, whole-home systems |

| Z-Wave | Reliable, less interference, good range | Requires hub/gateway, higher cost | Professional installations, security integration |

| WiFi | No hub required, direct cloud connection | Higher power consumption, network congestion | Powered sensors, standalone applications |

| Bluetooth Low Energy | Very low power, direct smartphone control | Limited range, smartphone proximity required | Portable sensors, simple applications |

| Thread/Matter | Future-proof, interoperability | Emerging standard, limited current support | Forward-looking installations |

| LoRaWAN | Very long range, extremely low power | Limited bandwidth, specialized infrastructure | Remote monitoring, industrial applications |

At SWITCH GO, we’ve found that Zigbee offers the best balance of power efficiency, reliability, and ecosystem compatibility for most sensor applications. However, we also offer WiFi options for customers seeking hub-free solutions.

Power Management

Power efficiency is critical for battery-operated sensors, directly impacting user experience through battery life:

| Power Source | Typical Battery Life | Advantages | Limitations | Best Applications |

|---|---|---|---|---|

| CR2032 coin cell | 6-18 months | Compact size, low cost | Limited capacity | Door/window sensors, small motion sensors |

| AA/AAA batteries | 1-3 years | Widely available, good capacity | Larger size | Motion sensors, environmental monitors |

| Rechargeable lithium | 3-6 months between charges | Environmentally friendly, cost-effective long-term | Requires recharging | High-use sensors, premium products |

| Hardwired (AC) | N/A | No battery replacement, consistent power | Installation complexity, location constraints | Fixed location sensors, high-power applications |

| Solar-assisted | 5+ years | Extended battery life, eco-friendly | Requires some light exposure | Environmental sensors, outdoor applications |

Our research indicates that consumers strongly prefer sensors with at least 12 months of battery life under normal usage conditions. Achieving this requires careful hardware design and efficient firmware that minimizes unnecessary wake cycles and transmissions.

Sensing Accuracy and Reliability

The core functionality of any sensor depends on its accuracy, reliability, and appropriate sensitivity:

| Sensor Type | Key Accuracy Metrics | Reliability Factors | Quality Indicators |

|---|---|---|---|

| Motion | Detection range, field of view, false positive rate | Consistent detection, environmental adaptability | Adjustable sensitivity, pet immunity |

| Temperature | Temperature accuracy (±°C), measurement range | Stability over time, response to rapid changes | Calibration capability, temperature compensation |

| Humidity | Relative humidity accuracy (±%RH), hysteresis | Long-term drift, condensation resistance | Calibration capability, temperature compensation |

| Door/Window | Gap tolerance, activation distance | Consistent triggering, mechanical durability | Magnet strength, alignment tolerance |

| Light | Lux accuracy, dynamic range | Consistency across light spectrum, drift | Human eye correlation, auto-calibration |

| Water Leak | Detection time, sensitivity to water volume | False alarm rate, corrosion resistance | Probe quality, circuit protection |

At SWITCH GO, we implement rigorous testing protocols for all our sensors, including environmental chamber testing, accelerated life testing, and field trials to ensure reliability under real-world conditions.

Form Factor and Installation

Physical design and installation simplicity significantly impact consumer satisfaction and adoption:

| Design Aspect | Consumer Impact | Design Considerations | Best Practices |

|---|---|---|---|

| Size | Aesthetic appeal, placement options | Component miniaturization, battery requirements | Minimize footprint while maintaining performance |

| Mounting options | Installation flexibility, stability | Surface compatibility, tool requirements | Provide multiple mounting options (adhesive, screws) |

| Visual design | Integration with home decor | Color options, material selection | Neutral colors, minimalist design |

| Setup process | Initial user experience | Pairing method, app guidance | QR code pairing, guided setup |

| Maintenance access | Long-term usability | Battery replacement, cleaning | Tool-free battery access, dust-resistant design |

Our consumer research shows that installation complexity is a leading cause of returns and negative reviews. Successful sensors must be designed for easy installation by non-technical users, with clear instructions and minimal tools required.

Data Processing and Intelligence

Modern smart sensors increasingly incorporate local processing capabilities that enhance functionality and reduce cloud dependency:

| Processing Capability | Benefits | Implementation Complexity | Value to Users |

|---|---|---|---|

| Local event detection | Faster response, works offline | Medium | High |

| False positive filtering | Reduced nuisance alerts | Medium-High | Very High |

| Pattern recognition | Predictive capabilities, insights | High | Medium-High |

| Edge AI | Advanced detection, privacy | Very High | High (for specific applications) |

| Firmware updateability | Long-term improvement, bug fixes | Medium | High |

The trend toward more intelligent sensors continues to accelerate, with even basic sensors now incorporating sophisticated algorithms to improve accuracy and reduce false alarms.

Manufacturing Considerations

For manufacturers and importers entering the smart sensor market, understanding the production challenges and solutions is essential for delivering competitive products.

Component Selection and Quality Control

The reliability of a smart sensor depends heavily on the quality of its components. Critical components include:

- Sensing elements: The primary detection component (PIR sensor, thermistor, reed switch, etc.) directly impacts core functionality. We recommend using components from established manufacturers with proven reliability.

- Microcontroller: The processing unit must balance performance with power efficiency. For battery-operated sensors, ultra-low-power MCUs like the Texas Instruments CC2640 or Silicon Labs EFR32 series offer excellent efficiency.

- RF module: For wireless connectivity, choosing certified RF modules can simplify the certification process and ensure reliable communication.

- Power management circuit: Particularly critical for battery-operated devices, efficient power management directly impacts battery life.

- Battery contacts and holders: Often overlooked, poor-quality battery contacts can lead to intermittent operation and customer dissatisfaction.

At SWITCH GO, our quality control process includes 100% functional testing of assembled units and a minimum 24-hour burn-in test for a sample from each production batch. This approach has helped us maintain a defect rate below 0.5%, significantly lower than the industry average of 1.5-2%.

Production Challenges and Solutions

Smart sensor manufacturing presents several challenges that importers should be aware of:

Challenge 1: Calibration and Consistency

Ensuring consistent performance across production batches requires careful calibration, particularly for environmental sensors. Our solution involves automated calibration stations that test and adjust each sensor against reference instruments, with calibration data stored in non-volatile memory.

Challenge 2: Miniaturization

As consumers demand smaller, more discreet sensors, fitting all components into compact designs becomes increasingly challenging. We address this through multi-layer PCB designs, careful component selection, and innovative 3D component arrangements.

Challenge 3: Battery Life Optimization

Achieving the long battery life consumers expect requires optimization at every level. Our approach includes low-power component selection, efficient firmware design, and comprehensive power consumption testing under various scenarios.

Challenge 4: Environmental Durability

Sensors must operate reliably across a wide range of environmental conditions. We implement environmental chamber testing for all designs, subjecting samples to temperature extremes, humidity variations, and thermal cycling to ensure durability.

Cost Optimization Strategies

For competitive pricing without compromising quality, consider these cost optimization approaches:

- Design for manufacturing (DFM): Simplifying assembly processes can reduce labor costs by 15-20%.

- Component consolidation: Using integrated chips that combine multiple functions can reduce both component and assembly costs.

- Automated testing: Investing in automated testing equipment reduces quality control costs in the long run and improves detection of defects.

- Packaging optimization: Efficient packaging design can reduce shipping costs by up to 25% for bulk shipments.

- Scale economies: Planning production volumes strategically can significantly impact unit costs. At SWITCH GO, we’ve found that production runs of 10,000+ units typically reduce per-unit costs by 12-18% compared to smaller batches.

Firmware and Software Development

The software component of smart sensors is increasingly important for product differentiation and functionality:

| Software Aspect | Importance | Development Considerations | Best Practices |

|---|---|---|---|

| Firmware efficiency | Critical for battery life | Power optimization, sleep modes | Minimize wake time, optimize transmission frequency |

| Wireless protocol implementation | Essential for connectivity | Standard compliance, interoperability | Use certified protocol stacks, extensive interoperability testing |

| Mobile app integration | Critical for user experience | Platform support, user interface | Intuitive design, comprehensive troubleshooting tools |

| Cloud backend | Important for remote access | Scalability, security | Implement robust encryption, regular security audits |

| API availability | Valuable for ecosystem integration | Documentation, stability | Follow standard practices, version control |

At SWITCH GO, we maintain dedicated firmware and software development teams that work alongside hardware engineers from the earliest design stages to ensure cohesive product development.

Sourcing Smart Sensors: A Guide for Importers

For importers looking to enter the smart sensor market, selecting the right manufacturing partner is perhaps the most critical decision. Based on SWITCH GO’s experience as both a manufacturer and market participant, we offer the following guidance.

Evaluating Manufacturers and Suppliers

When assessing potential smart sensor suppliers, consider these key factors:

- Certification expertise: Verify that the manufacturer has successfully obtained relevant certifications for your target markets. Request sample certificates and test reports from previous products.

- Manufacturing capabilities: Assess production capacity, quality control processes, and technical expertise. A factory tour (virtual or in-person) can provide valuable insights.

- R&D capabilities: Determine whether the supplier can assist with customization and product improvements. This becomes particularly important for developing differentiated products.

- Business stability: Research the company’s history, client references, and financial stability. Suppliers with at least 3-5 years in the smart home industry typically offer more reliable partnerships.

- Communication and responsiveness: Evaluate communication quality during initial interactions. Prompt, clear communication often indicates better ongoing support.

Sample Testing and Verification

Before committing to large orders, thorough sample testing is essential:

- Functional testing: Verify all features work as specified, including detection accuracy, wireless range, and battery performance.

- Compatibility testing: Confirm compatibility with popular smart home platforms and hubs.

- Environmental testing: Test performance under various conditions (temperature, humidity, lighting).

- Durability testing: Assess build quality, drop resistance, and long-term reliability.

- User experience evaluation: Have potential customers test the product and provide feedback on the physical design and app interface.

At SWITCH GO, we recommend requesting at least 10-15 samples for comprehensive testing and being wary of suppliers unwilling to provide adequate samples for evaluation.

MOQ Negotiations and Pricing Structures

Minimum Order Quantity (MOQ) requirements can be a significant barrier for new importers. Effective negotiation strategies include:

- Phased ordering: Negotiate a smaller initial order with a commitment to larger follow-up orders upon successful market testing.

- Multiple product ordering: Combine orders for different products from the same manufacturer to reach MOQ thresholds.

- White-label options: Consider starting with a manufacturer’s existing design (white-labeled with your brand) to reduce MOQ requirements before investing in custom designs.

Typical pricing structures in the industry include:

| Order Volume | Expected Discount from Base Price |

|---|---|

| Sample quantities | 0% (often at premium) |

| MOQ (typically 1,000-2,000 units) | 0-5% |

| 5,000-10,000 units | 5-10% |

| 10,000-50,000 units | 10-15% |

| 50,000+ units | 15-25% |

Lead Times and Logistics Planning

Realistic lead time expectations are crucial for inventory planning:

- Development timeline: For custom designs, expect 2-3 months from concept to production-ready samples.

- Certification process: Allow 1-3 months for certification, depending on the regions targeted.

- Production lead time: Typically 30-45 days from order confirmation to shipping for standard orders.

- Shipping time: Sea freight typically takes 30-45 days to North America or Europe, while air freight reduces this to 5-10 days but at significantly higher cost.

For effective logistics planning, we recommend:

- Buffer inventory: Maintain at least 45-60 days of inventory to account for production and shipping delays.

- Phased shipping: Consider splitting large orders into multiple shipments to balance inventory costs with availability.

- Inspection services: Engage third-party inspection services for quality verification before shipment.

Value-Added Features That Drive Sales

In the competitive smart sensor market, differentiation through value-added features can significantly impact market success. Based on SWITCH GO’s market research and sales data, these features deliver the strongest consumer appeal:

Multi-Sensor Functionality

Combining multiple sensing capabilities in a single device offers several advantages:

- Cost efficiency: Lower total cost compared to multiple single-function sensors.

- Installation simplicity: Fewer devices to install and maintain.

- Correlated data: Enhanced insights from combined data streams (e.g., temperature and humidity together).

- Space efficiency: Particularly valuable in smaller homes and apartments.

Popular multi-sensor combinations include:

| Combination | Consumer Appeal | Implementation Complexity | Market Potential |

|---|---|---|---|

| Motion + Temperature + Humidity | Very High | Medium | Excellent |

| Door/Window + Temperature | Medium | Low | Good |

| Motion + Light | High | Low | Very Good |

| Temperature + Humidity + Light + Air Quality | Very High | High | Excellent (Premium) |

Our data shows that multi-sensor devices can command a 30-50% price premium over single-function sensors while offering better perceived value to consumers.

Advanced Notification Options

Sophisticated alert capabilities enhance user experience and product value:

- Customizable thresholds: User-defined trigger points for environmental conditions.

- Conditional alerts: Notifications based on multiple conditions (e.g., temperature drop only when home is unoccupied).

- Escalating notifications: Progressive alert systems that escalate based on severity or lack of response.

- Notification routing: Options to direct alerts to different users based on type or time.

These notification features transform sensors from simple monitoring devices to proactive home management tools.

Ecosystem Integration

smart sensor applications

Deep integration with smart home platforms significantly enhances value:

- Multi-platform compatibility: Support for multiple ecosystems (Amazon Alexa, Google Home, Apple HomeKit, Samsung SmartThings).

- Trigger capabilities: Ability to initiate automations based on sensor data.

- Scene participation: Integration into broader home scenes or routines.

- Data sharing: Contributing sensor data to whole-home dashboards and analytics.

At SWITCH GO, we ensure our sensors are compatible with all major smart home ecosystems, including Tuya, EweLink, Amazon Alexa, Google Home, and SmartThings, maximizing their appeal to diverse consumer segments.

Historical Data and Analytics

Access to historical sensor data provides valuable insights and enhances product value:

- Trend visualization: Graphical representation of environmental changes over time.

- Pattern recognition: Identification of recurring patterns in sensor data.

- Comparative analysis: Benchmarking against historical norms or similar households.

- Predictive insights: Forecasting future conditions based on historical patterns.

These analytics features transform sensors from reactive devices to proactive tools for home management and optimization.

Enhanced Security Features

For security-oriented sensors, advanced features provide meaningful differentiation:

- Tamper detection: Alerts when sensors are physically manipulated.

- Signal jamming detection: Identification of potential wireless interference.

- Backup communication: Secondary notification paths if primary connectivity fails.

- Local storage: Retention of event data during internet outages.

These security enhancements are particularly valuable for sensors used in home security applications and can justify premium pricing.

Case Study: SWITCH GO’s Smart Sensor Success Story

At SWITCH GO, our journey in the smart sensor market offers valuable insights for importers and manufacturers. Our flagship MS-300 Multi-Sensor illustrates the path from concept to market success.

Product Development Journey

Our development process began with comprehensive market research, identifying a gap for an integrated multi-sensor with superior battery life and ecosystem compatibility. Key development milestones included:

- Initial concept and requirements gathering: 4 weeks

- Competitive analysis of 18 leading products

- Focus groups with 60+ potential users

- Technical requirement specification

- Design and prototyping: 8 weeks

- Sensor selection and integration

- Power management optimization

- Industrial design for discreet aesthetics

- Initial prototype production and testing

- Software development: 10 weeks (concurrent with hardware)

- Firmware optimization for power efficiency

- Mobile app integration

- Cloud infrastructure setup

- Smart home platform integration

- Testing and refinement: 6 weeks

- Beta testing with 100 users

- Environmental chamber testing

- Battery life verification

- Wireless range optimization

The entire development cycle took approximately 6 months from concept to production-ready design, with an investment of approximately $130,000 in R&D.

Certification Process Overview

Our certification strategy prioritized major markets while managing costs:

- Pre-certification preparation: Internal testing against certification requirements to identify potential issues early.

- Certification body selection: We selected globally recognized testing laboratories with experience in IoT devices.

- Simultaneous submissions: We pursued FCC, CE, and other certifications concurrently to minimize time-to-market.

- Documentation preparation: Comprehensive technical files were prepared in-house to reduce consultant costs.

The certification process took approximately 8 weeks and cost $12,000 across all target markets. This investment proved worthwhile, as it enabled access to all major global markets and retail channels.

Market Entry Strategy

Our go-to-market approach focused on building credibility before pursuing volume:

- Initial launch: Limited release through our direct-to-consumer website to gather real-world feedback and refine marketing messaging.

- Online marketplace expansion: Expansion to Amazon and other e-commerce platforms, with heavy investment in product photography and detailed listings.

- Retail partnerships: Leveraging initial success to secure placement with specialty smart home retailers.

- OEM/ODM opportunities: Offering white-label and customized versions to established brands looking to expand their smart home offerings.

This phased approach allowed us to refine our product and messaging before committing to large production volumes.

Customer Feedback and Continuous Improvement

Post-launch, we implemented a structured feedback loop:

- Automated feedback collection: In-app surveys at key usage milestones.

- Review monitoring: Systematic analysis of online reviews to identify common praise and complaints.

- Support ticket analysis: Monthly review of support issues to identify potential product improvements.

- Firmware and app updates: Regular updates based on user feedback, with an average release cycle of 6-8 weeks.

This approach led to several significant improvements:

- Enhanced motion detection algorithms reducing false positives by 40%

- Optimized battery life, extending typical operation from 12 to 18 months

- Added customizable alert thresholds for environmental conditions

- Improved wireless range through antenna optimization

Future Trends in Smart Sensor Technology

As we look toward the future of smart sensor technology, several emerging trends will shape the market landscape. Importers and manufacturers should consider these developments when planning their product roadmaps.

Matter Protocol Adoption

The Matter protocol, backed by major technology companies including Amazon, Apple, Google, and Samsung, promises to revolutionize smart home interoperability. For smart sensors, Matter adoption offers several advantages:

- Simplified certification: A single certification process covering multiple ecosystems.

- Enhanced interoperability: Seamless operation across different smart home platforms.

- Improved reliability: Local control capabilities reducing cloud dependency.

- Stronger security: Standardized security requirements and implementation.

At SWITCH GO, we’re already incorporating Matter compatibility into our product development roadmap, with our first Matter-certified smart sensors scheduled for release in Q3 2025.

AI-Powered Sensing

Artificial intelligence is increasingly being applied to sensor data to deliver enhanced functionality:

- Advanced pattern recognition: Identifying complex patterns beyond simple thresholds.

- Anomaly detection: Recognizing unusual conditions that might indicate problems.

- Predictive analytics: Forecasting future conditions based on historical patterns.

- Contextual awareness: Understanding sensor data in the broader context of home activities.

These AI capabilities transform sensors from simple data collection devices to intelligent home assistants that provide actionable insights.

Energy Harvesting

Emerging energy harvesting technologies promise to reduce or eliminate battery replacement:

- Photovoltaic: Small solar cells that harvest indoor or outdoor light.

- Thermal: Generating power from temperature differentials.

- Kinetic: Harvesting energy from motion or vibration.

- RF harvesting: Capturing energy from ambient radio waves.

While still emerging, these technologies could eventually eliminate one of the primary pain points of wireless sensors – battery replacement – and enable placement in previously impractical locations.

Miniaturization and Aesthetics

As smart home adoption moves beyond early adopters to the mainstream market, aesthetic considerations become increasingly important:

- Invisible sensors: Ultra-compact designs that blend seamlessly into home environments.

- Decorative integration: Sensors incorporated into decorative elements or furniture.

- Flexible form factors: Adaptable designs that can be customized to different environments.

- Premium materials: Higher-end finishes and materials that complement luxury home design.

These aesthetic improvements address the concerns of design-conscious consumers who have been hesitant to adopt visibly technological products in their homes.

Health and Wellness Applications

Smart sensors are increasingly expanding beyond traditional environmental monitoring to support health and wellness:

- Air quality monitoring: Detailed tracking of pollutants, allergens, and VOCs.

- Sleep environment optimization: Sensors that monitor and help optimize sleeping conditions.

- Behavioral insights: Activity patterns that might indicate health issues.

- Preventive alerts: Early warning of conditions that could impact health (mold risk, extreme temperatures).

This trend represents a significant opportunity for sensor manufacturers to expand into the growing health tech market while leveraging existing smart home infrastructure.

FAQ Section

Certification and Compliance

Q: What certifications are absolutely essential for selling smart sensors in the US market?

A: For the US market, FCC certification is essential for all wireless sensors to ensure compliance with radio frequency regulations. If your sensor connects directly to household power (rather than using batteries), UL or ETL certification is typically required for safety compliance. Battery-operated sensors generally don’t require UL certification unless they present specific safety risks. Additionally, if your sensor integrates with specific ecosystems like Apple HomeKit, you may need to complete their certification programs as well.

Q: How do privacy regulations like GDPR affect smart sensor design and marketing?

A: Privacy regulations significantly impact smart sensors that collect potentially sensitive data. Key requirements include: 1) Implementing data minimization principles, collecting only necessary information; 2) Providing clear privacy policies explaining what data is collected and how it’s used; 3) Ensuring secure data transmission and storage; 4) Offering users control over their data, including the ability to delete it; and 5) Obtaining appropriate consent for data collection. At SWITCH GO, we implement privacy-by-design principles in all our sensors, minimizing cloud data storage and prioritizing local processing where possible.

Q: Can I use the same certifications for different types of sensors, or does each product require separate certification?

A: While some certification aspects can be leveraged across product lines, most certifications are product-specific and require individual testing and documentation. However, if you have a family of products with identical wireless components and similar designs, you may be able to use a modular approach where certain components (like the radio module) are certified once and then incorporated into multiple products. This approach can reduce certification costs and timelines for subsequent products, but still requires some product-specific testing.

Technical Specifications

Q: What’s the typical battery life I should expect from a well-designed wireless sensor?

A: Battery life varies significantly based on sensor type, functionality, and communication protocol. As a general guideline: Door/window sensors should achieve 18-24+ months on a CR2032 battery; motion sensors typically last 12-18 months on AA batteries; temperature/humidity sensors should operate for 12-24 months depending on reporting frequency; and multi-sensors generally achieve 10-16 months of operation. Battery life can be significantly extended by optimizing reporting intervals, implementing efficient sleep modes, and using energy-harvesting technologies where applicable.

Q: How do I choose between Zigbee, Z-Wave, and WiFi for my sensor products?

A: This decision should be based on several factors: 1) Power requirements – Zigbee and Z-Wave are significantly more power-efficient than WiFi, making them better for battery-operated devices; 2) Ecosystem compatibility – consider which smart home systems your target customers use; 3) Range requirements – Z-Wave typically offers better range than Zigbee, while WiFi range depends on the home network; 4) Hub requirements – WiFi connects directly to the router while Zigbee and Z-Wave require hubs; and 5) Cost considerations – WiFi modules are generally less expensive, but the power requirements may necessitate larger batteries or power supplies. At SWITCH GO, we primarily use Zigbee for its excellent balance of power efficiency, reliability, and ecosystem compatibility.

Q: What sensing accuracy should I expect from consumer-grade smart sensors?

A: Reasonable accuracy expectations for consumer-grade sensors are: Temperature sensors: ±0.5°C to ±1.0°C; Humidity sensors: ±3% to ±5% RH; Light sensors: ±10% to ±15% of reading; Motion detection: 98%+ detection rate at specified range with less than 5% false positives; Door/window sensors: 99%+ reliable activation within specified gap distance. Higher accuracy is possible but typically increases costs. For most smart home applications, these accuracy levels provide a good balance of performance and affordability.

Importing and Manufacturing

Q: What’s a realistic minimum order quantity (MOQ) for custom-designed smart sensors?

A: For fully customized smart sensors with unique hardware and firmware, typical MOQs range from 2,000-5,000 units. For semi-customized products (standard hardware with custom firmware and branding), MOQs may be lower, around 1,000-2,000 units. White-label products with only branding customization might be available with MOQs as low as 500 units. These figures can vary significantly based on the manufacturer and the complexity of customization. At SWITCH GO, we offer flexible MOQ options depending on the level of customization required.

Q: How can I verify that a manufacturer’s sensors will work reliably with popular smart home platforms?

A: Request specific evidence of compatibility, including: 1) Certification documentation from the platform providers (Works with Alexa, Google Home compatible, etc.); 2) Video demonstrations showing the actual integration process and functionality; 3) Access to test samples that you can evaluate with your target platforms; 4) References from existing customers who are using the sensors with these platforms; and 5) Detailed API documentation if you’re planning to develop custom integrations. Be wary of vague compatibility claims without supporting evidence, as integration quality can vary significantly.

Q: What quality control measures should I expect from a reliable manufacturer?

A: A reputable smart sensor manufacturer should implement multiple quality control stages: 1) Component inspection and testing before assembly; 2) In-line quality checks during production; 3) 100% functional testing of finished products, including sensor calibration verification; 4) Wireless performance testing in controlled environments; 5) Battery performance verification; 6) Environmental testing (temperature, humidity resistance); and 7) Batch sample testing for durability and long-term performance. Ask potential manufacturers about their defect rate, testing procedures, and quality control documentation.

Market and Business Considerations

Q: How can I differentiate my smart sensor product in a crowded market?

A: Differentiation can come through several avenues: 1) Enhanced accuracy or reliability compared to competitors; 2) Superior battery life through optimized power management; 3) Multi-sensor functionality that provides better value than single-function alternatives; 4) Unique design that blends better with home decor; 5) Advanced analytics and insights derived from sensor data; 6) Specialized features for specific use cases or environments; or 7) Exceptional ecosystem integration that simplifies the user experience. At SWITCH GO, we’ve found that focusing on multi-sensor functionality and battery life optimization has allowed us to stand out in competitive markets.

Q: What pricing strategy works best for new entrants to the smart sensor market?

A: For new market entrants, a value-based pricing strategy often works best – identifying the specific value your product delivers compared to alternatives and pricing accordingly. Consider a good-better-best product strategy with different feature sets at various price points to address different market segments. As a general guideline, basic door/window sensors typically retail for $20-30, motion sensors for $25-40, environmental sensors for $30-50, and premium multi-sensors for $45-70. Initial pricing slightly below established competitors can help gain market traction, but avoid competing solely on price as this can trigger race-to-bottom dynamics.

Q: How important is packaging and retail presentation for smart sensors?

A: Packaging plays a crucial role in retail success, particularly for products targeting retail channels. High-quality packaging: 1) Communicates product value and features effectively; 2) Differentiates your product on crowded retail shelves; 3) Protects the product during shipping and handling; 4) Provides clear setup instructions that reduce support costs; and 5) Reinforces brand identity and positioning. Invest in professional packaging design that clearly communicates your product’s key benefits and differentiators, with high-quality graphics and materials appropriate for your price point and retail channels.

Conclusion

The smart sensor market presents a compelling opportunity for importers and manufacturers in 2025 and beyond. With strong growth projections, increasing consumer adoption, and evolving feature sets, smart sensors continue to serve as the foundation of truly intelligent homes.

Success in this competitive landscape requires attention to several key factors:

- Technical excellence: Delivering reliable performance, accuracy, and battery life that meet or exceed consumer expectations.

- Ecosystem compatibility: Ensuring seamless integration with popular smart home platforms and devices.

- Manufacturing quality: Implementing rigorous quality control to build consumer trust and minimize returns.

- Value-added features: Differentiating products through multi-sensor functionality, advanced analytics, and intuitive user experiences.

- Forward-looking development: Anticipating market trends like Matter adoption and AI integration.

At SWITCH GO, we’re committed to advancing smart sensor technology and supporting our partners in navigating this dynamic market. Our expertise as both manufacturers and market participants gives us unique insights into the challenges and opportunities in the smart home ecosystem.

Founded in 2019 with our philosophy of “Switch Smarter, Live Easier,” we’ve established ourselves as a leading provider of smart home solutions based in Shenzhen. Our products are compatible with all major smart home platforms including Tuya, EweLink, Amazon Alexa, Google Home, and SmartThings, ensuring maximum market reach and consumer satisfaction.

For importers and manufacturers looking to enter or expand in the smart sensor market, we offer consultation services, OEM/ODM manufacturing capabilities, and certification support. Contact our team to discuss how we can help you succeed in the smart sensor market.

This article was produced by SWITCH GO, a leading smart home technology company based in Shenzhen, China. With our founding in 2019 and our commitment to helping consumers “Switch Smarter, Live Easier,” SWITCH GO combines technical expertise with market insights to deliver innovative solutions for global markets.